09211616

Read more about our different types of strapping material below.

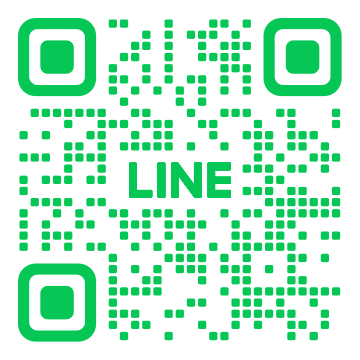

For more information or a tailored advice you can contact us without any obligations. We’re happy to help you!

Steel is the oldest and strongest strap available. Steel strap was designed for extreme tasks for which a heavy or very firm strap is needed, whereby a high strength and minimum stretch is required, or when the product can be sharp or hot.

Steel strap has virtually no stretch. As a result, almost no tension is lost after strapping. Steel straps are mainly used in the wood and metal sector, but can also be used for other heavy materials. Steel straps are available in different qualities, widths, thicknesses and finishes, such as galvanised, glued, painted or zinc-coated.

Click here for our different types of steel strap.

Today, PET strap is a good and cost-effective alternative for steel strap.

Polypropylene or PP straps are the most commonly used straps and are used in a wide range of industries. This strap is economical in price and can be used in many applications. Polypropylene was specially designed for light to medium heavy loads and has an excellent performance under normal conditions, because properties such as breaking strength, elasticity and tension loss are sufficient for many applications. It is available in different widths, thicknesses, compositions and colours and can be easily printed with, for example, warnings, quality marks or marketing messages.

The disadvantages of PP strap are that is more sensitive to ambient factors and it’s low stretch recovery

Here you can see the different types of PP strap.

Polyester is the strongest plastic strap. It is often used for heavy loads that require a high tension during handling, transport and storage. PET straps offer high tension, are able to retain this tension for a long period of time and have an excellent stretch recovery. Because of the stretch recovery, they are excellently resistant to shocks and impacts. PET strap is light, UV resistant, recyclable and easy to handle. These properties remain, even at high temperatures. The main disadvantages is that it is less elastic than PP strap.

In many industries, PET is used as an alternative for steel. Here you can read why this is a good idea.

Click here for the different types of PET strap.

Notifications