What does a carton sealer do?

Taping is applying an adhesive tape to, for example, a box or other surface. This can be done manually, with a tape dispenser or with a carton sealer. In the packaging industry, tape is often used to close something. In most cases a box or packaging. In addition, tape is also used to bundle products, mark them, communicate a message or prevent theft. The goal of taping is to store and / or send your products damage-free, so that they arrive at your customer in perfect condition.

Adhesive tape is available in various qualities, designs and in most cases consists of two parts: the carrier and the adhesive layer.

Types of adhesive layer on tape

There are different types of adhesive layer:

Solvent glue: solvent glue is a strong type of glue and offers long-term adhesive strength. This type of glue is therefore recommended for longer storage periods or for sealing that must resist moisture, dust and temperature fluctuations.

Acrylic glue: this glue is water-based and therefore recyclable. It is a transparent adhesive and suitable for closing colored and / or printed boxes. With acrylic glue, the immediate tack (first tack) is less strong.

Hotmelt: this glue is made from a synthetic rubber. Hotmelt has a good initial adhesion, is environmentally friendly and resistant to moisture. It is particularly suitable for short-term use.

Gum layer: activated by moistening and gives a very good adhesion. It ensures that the two parts are “fused” together, creating a permanent bond.

Types of carriers on tape

The most common types of tape are PP, PVC tape and paper tape.

PP tape is a high-quality tape and has a very high tensile strength. In addition, it is an inexpensive tape. Characteristic of PP (polypropylene) tape is the high resistance in the length and width direction. PP tape is easy to unroll and suitable for closing light to heavy boxes, depending on the glue type. The adhesives acrylic and hotmelt are mainly combined with the PP carrier.

PVC tape can be torn by hand, is moisture resistant and easy to print. Because PVC tape is not stretchable in the length direction, the material is ideal for closing boxes with a high valve tension. Click here for more information about PP and PVC tape.

Paper tape is the environmentally friendly solution for closing your boxes. The packaging box can be recycled in its entirety after use, including the tape. Due to the direct and strong adhesion, paper tape is particularly suitable for closing heavy and / or valuable packaging. Paper tape can be divided into two types: self-adhesive and gummed. Click here for more information about paper adhesive tape.

Which packaging tape and carton sealer are best?

Important factors that play a role in choosing which packaging tape and which carton sealer are most suitable include:

- What will you use the packaging tape for?

- How heavy is the load and how great is the valve tension?

- Are your boxes different in size? Or do you work in series?

- What are the environmental factors, such as moisture, dust and temperature?

- Do you want good protection against theft?

- Do you want to print packaging tape?

- How do you want to process packaging tape: manually or by carton sealer machine?

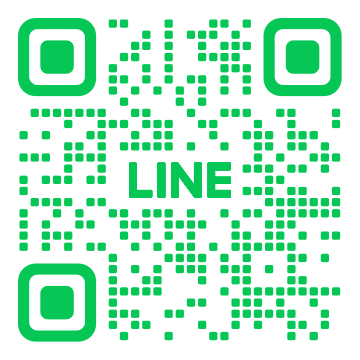

You can determine the best packaging tape and carton sealer for you, together with our experienced specialists. Please do not hesitate to contact us.

Devices and tape machines

Packaging tape or adhesive tape can be applied manually, with a table dispenser or by machine with a carton sealer.

Manual: often in combination with a hand dispenser. Easy, mobile and cheap. For larger numbers, with repetitive dimensions or at a fixed workplace, it is recommended to work with a dispenser or machine.

Table dispenser: With a table dispenser, the cut length of the adhesive tape can be set in advance, so that the correct length is always dispensed and automatically cut. This saves tape and time.

Machine: with a carton sealer it is possible to easily seal thousands of packages a day. Click here for the semi-automatic carton sealers. Click here for all (fully) automatic carton sealers.