09211616

Strapping is often used to stabilise a pallet of bricks or stones. In some cases, strapping with a steel band is still used, but these days a PET strapping band is usually used. This is due to its excellent features such as its elastic capacity and ability to maintain tension for long periods. Furthermore, PET is cheaper than steel band and less harmful to the environment.

For some types of stones, the load is fitted with a top sheet. A top sheet is a layer of plastic film that is laid on top of the package. The top sheet is attached using strapping. The top sheet protects the stones against dirt and moisture from above, but can also serve to display information such as product details. These can be printed on the film using a High Resolution Inkjet Printer, for example.

Roof tiles are transported by pallet. On site, the roof tiles are placed on the roof as a parcel. A widely-used method of creating these parcels is strapping. A plastic strapping band holds the roof tiles together and also acts as a handling system. The band is usually attached by an automatic strapping machine.

Swift operation and reliability are very important for these machines.

When trees leave the sawmill, they are transported as planks, beams and frames to the timber industry, for example furniture manufacturers or timber yard.

Before delivery, the wood is sorted by quality and into standard sizes, and then bundled. In the past, wire was used to keep the load together. Following the use of wire came the era of the steel band. Both applications have a common disadvantage: It becomes detached. As a result, the bundle is no longer held together. In addition, both wire and steel bands leave rust marks.

These days, plastic strapping is used as an ideal (and cheaper) alternative for bundling wood.

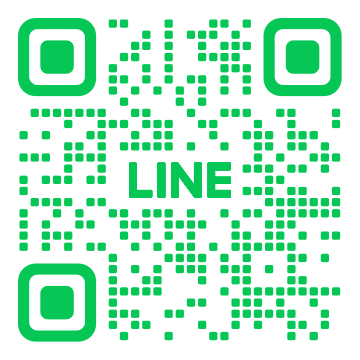

Want to know more? Then do not hesitate to contact us.